Timelapse Frieren Knit Sweater (1)

In-stock items typically ship within 2 to 4 business days if purchased on their own. If your order includes a pre-order item, the entire order will ship together once the pre-order is ready. If you would like in-stock items to ship sooner, you may request split shipping at checkout or contacting us.

IMPORTANT: This first batch of pre-orders is sold out! Click here for the second batch. Thank you to everyone who ordered! We will be working hard to deliver ASAP!

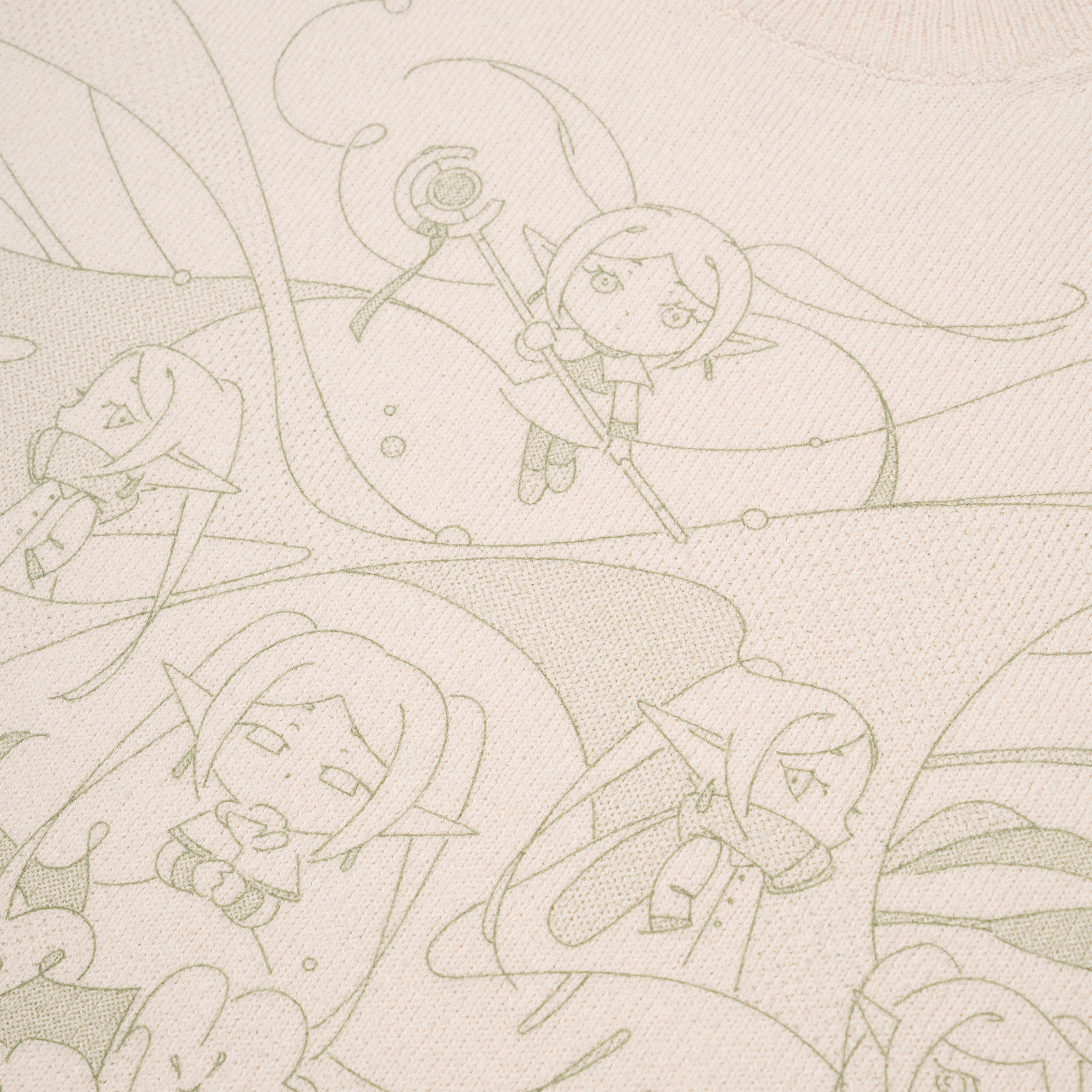

A luxe statement knit sweater that still has everyday comfort and appeal. In honor of Frieren: Beyond Journey's End Seasons 1's unique ED visuals, this piece uses beautiful screen printed linework of multiple Frierens entangled in magic and Blue-Moon Weed florals. Where timeless storytelling meets everyday style.

Has an easy fit but is true to size. 60% recycled cotton blended with 40% cool jade recycled polyester twisted yarn knit fabric.

Illustration in collaboration with Genie Ink (@genniieeee).

Male model (Henry) height 6'0", seen wearing M

Female model (Lauren) height 5'2", seen wearing M

Machine wash on delicate low. Air dry or tumble dry on delicate to reduce any undesired shrinkage and to preserve garment shape and print quality.

It's recommended to avoid using fabric softeners.

IMPORTANT: For the OTV | Frieren collection, direct shipping is only offered to North America. This is because our license to distribute our products is only approved in this region.

If you live outside of NA and are still interested, please reach out to store@offlinetv.com and put “Frieren International Order Forwarding” in the subject line, and we can recommend a trusted forwarder.

Our team's goal to bring iconic elements of the beloved series into wearable & fashionable garments.

Jacquard Knit

A subtle "otv" jacquard knit - reversed stitched to create a debossed effect.

Engineered Screen Print

All-over linework print referencing Season 1's unique ED visuals. Entangled in magic & Blue-Moon Weed florals.

Our approach to

Materials & The Details.

Custom designed from the ground up, from fit to fabric to artwork - this piece is a true labor of love from the OfflineTV team.

We took multiple ends of a finer yarn and twisted them together to create a thick 5gg yarn (stitches/inch), giving the piece a premium weighted feel & luxurious texture without becoming too chunky.

Our yarn is sustainably made from mixing a recycled cotton with a recycled Cool Jade polyester. The Cool Jade adds quick dry properties, making this the perfect lightweight sweater that transitions seamlessly between seasons.

On the back of the sweater, there's a subtle "otv" jacquard knit - reversed stitched to create a debossed effect.

Print quality that does the illustration & artwork justice.

FAQ

more Q&A found here

Do you ship overseas?

IMPORTANT: For the OTV | Frieren collection, direct shipping is only offered to North America. This is because our license to distribute our products is only approved in this region.

If you live outside of NA and are still interested, please reach out to store@offlinetv.com and put “Frieren International Order Forwarding” in the subject line, and we can recommend a trusted forwarder.

IMPORTANT:

If an international forwarding order is received and includes a pre-order item, the entire shipment will be sent together once the pre-order is ready. Shipping things together will save you a lot of money. If you cannot wait and want what's in stock immediately, leave us a note in your outreach email.

Pre-orders & pricing

We pour a lot of care and detail into creating our premium collections, and we want to be transparent about how pricing works. Every piece starts with the cost of design, materials, and the skilled factory labor that goes into constructing each garment. From there, we have licensor royalties, which allow us to bring unique and meaningful designs to life. A portion also goes to our licensing agents, who help us secure these opportunities. Finally, there’s the cost of running the operation—paying our team to build the website, provide customer service, and ensure each launch runs smoothly.

Our goal is to bring you high-quality, thoughtfully crafted apparel while balancing the costs of making it happen. Thank you for supporting not just the products, but the people and processes behind them.